Introduction to Thread Rolling Machines

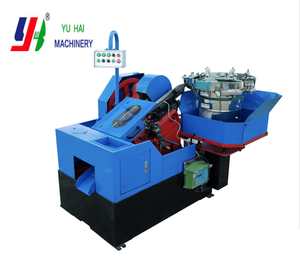

Thread rolling is a precise and efficient method of producing threads on screws, bolts, and nails, which is integral to numerous industries. The thread rolling machines on Alibaba.com cater to this need with advanced technology and varied specifications to suit different production requirements.

Types and Applications

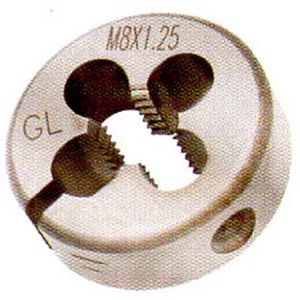

The diversity of thread rolling equipment ranges from flat die to cylindrical die versions. Flat die machines are ideal for threads with limited length, while cylindrical ones accommodate longer threads. These machines are pivotal in automotive, construction, and manufacturing sectors for creating robust threaded components.

Operational Features

Equipped with variable speed controls, the thread rolling machinery offers versatility in operation. The integration of electro-hydraulic functions in automatic models allows for seamless transition between semi-automatic and fully automatic modes, tailoring to both bespoke and mass production needs.

Technical Specifications

The thread rolling units are designed to work with a standard 380V voltage and 50Hz frequency, ensuring compatibility with industrial power supplies. With a capacity to produce an average of 10 pieces per day, these machines are built to accommodate high-volume thread processing with radial or axial threading capabilities.

Material and Design Advantages

Durability is at the forefront of the thread rolling systems available. The wear-resistant motors and power distribution boxes are engineered for longevity, even in high-frequency quenching processes. The compatibility with special molds allows for the production of various nail types, including abnormal shapes and threaded nails.

Operational Efficiency and Maintenance

The design of these machines emphasizes operational efficiency with features like low noise levels and anti-vibration technology, ensuring minimal disruption. The self-suction and anti-fouling features of each unit underscore the ease of maintenance, making them a reliable choice for continuous production environments.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4