Popular in your industry

Top categories

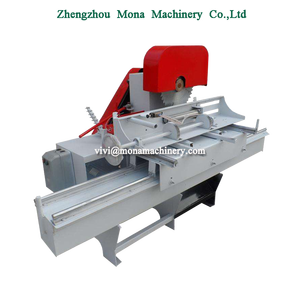

About table circular saws

Introduction to Table Circular Saws

Table circular saws are essential tools in the machinery industry, used for cutting various materials such as wood, plastic, and metal with precision and efficiency. These saws consist of a circular blade mounted on an arbor, powered by an electric motor. They are commonly used in woodworking, carpentry, and construction for making straight and angled cuts. Table circular saws offer versatility, accuracy, and speed in cutting different materials, making them indispensable in various industrial applications.

Design and Functionality

The design of table circular saws typically includes a flat table surface with an adjustable blade that can be tilted to different angles for bevel cuts. The blade guard ensures operator safety during operation, while the rip fence guides the material for straight cuts. These saws may also feature dust collection systems to maintain a clean working environment. The functionality of table circular saws lies in their ability to make precise cuts quickly, making them ideal for high-volume production environments.

Technical Specifications

Table circular saws come in various sizes ranging from compact benchtop models to large industrial-grade machines. The power capability of these saws can vary from 1 HP for smaller models to over 5 HP for heavy-duty industrial saws. Blade sizes range from 8 inches to 12 inches or more, with different tooth configurations for cutting specific materials. The cutting depth and angle adjustments allow for versatile cutting operations to meet different project requirements.

Features and Advantages

One of the key features of table circular saws is their portability and ease of setup, making them suitable for both on-site and workshop use. The ability to make precise and repeatable cuts enhances productivity and accuracy in various woodworking and construction applications. The adjustable blade angles and cutting depths provide flexibility for different cutting tasks, while safety features such as blade guards and emergency stop mechanisms ensure operator safety.

Choosing the Right Table Circular Saw

When selecting a table circular saw, consider factors such as the intended use, cutting capacity, power requirements, and safety features. Choose a saw that matches the materials you will be cutting and the frequency of use. Look for additional features such as laser guides for accuracy, dust extraction systems for a cleaner work environment, and sturdy construction for durability. It's essential to invest in a quality table circular saw that meets your specific cutting needs.

Maintenance and Care

To ensure optimal performance and longevity of your table circular saw, regular maintenance is crucial. Keep the blade clean and sharp for efficient cutting operations, and check for any signs of wear or damage on the blade and other components. Lubricate moving parts as recommended by the manufacturer and inspect safety features regularly. Proper storage and handling of the saw when not in use can also extend its lifespan and maintain performance.