Popular in your industry

Top categories

About soft plastic molds

Soft plastic molds are used to create replicas of an original object out of soft, pliable plastic. They are often made from silicone, resin, rubber, and materials that can be injected, poured, or pressed with soft plastic to produce detailed copies. The molds are created by making a master model out of clay, wax, or another material, coating it in silicone or rubber, and allowing it to cure. The mold can then be filled repeatedly with liquid plastic to produce soft plastic lure molds. The soft, rubbery texture allows the mold to flex as the plastic cools, releasing the finished piece easily. Check out a wide range of molds for soft plastic on Alibaba.com.

Uses of soft plastic molds

Soft plastic molds are widely applied in different industries, soft plastic fishing molds being common. These tools enable anglers to duplicate proven lure designs and experiment with new shapes, colors, and modifications. Pouring soft plastics into molds is an easy, affordable way to create a large variety of lures for different fishing conditions. Another common use is producing soft plastic bait replicas like worms, grubs, crawfish, and insects for fishing. The soft molds create true-to-life bait with details that mimic live specimens. Beyond fishing tackle, soft plastic molds are used to produce detailed miniatures for model trains, architectural models, and dollhouses. Silicone molds capture fine features, engravings, and textures from the master model.

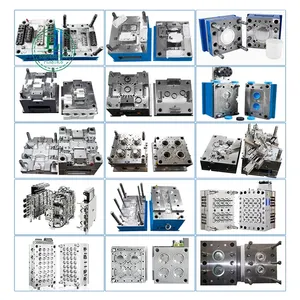

Types of soft plastic molds

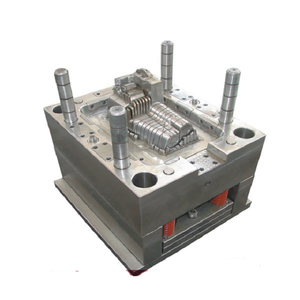

Soft plastic molds come in different types based on their material and production methods. For instance, silicone molds are made from pourable silicone that cures into flexible, stretchy rubber. They offer high precision and durability for repeated casting. Resin molds, on the other hand, are made by coating the master model in liquid resin that hardens into a stiff mold. These molds are more affordable but less flexible than silicone. There are also rubber molds, which are made using pourable latex rubber. They are good for molding simple geometries and flat items. Aluminum soft plastic molds are also available on the market. They can be used to create soft plastic molds. These are lightweight, quick to produce, and offer high precision and consistency for casting while being more durable and heat-resistant than silicone or rubber molds.

Do soft plastic molds break down?

One downside of soft plastic molds is that they eventually wear out and need to be replaced. The molds can only withstand a certain number of casting cycles before the material starts to break down. Thermoplastic materials like polyvinyl chloride (PVC) and plastisol tend to erode silicone and rubber molds more quickly than thermoset polymers like epoxy resin. Using mold releases and carefully controlling casting temperatures can extend the mold life. With proper care, silicone molds can produce 50 to over 100 castings, while resin, latex, and rubber molds may only last for 10 to 20 uses before deterioration. Replacing worn-out molds ensures cast parts meet quality standards.