Popular in your industry

Top categories

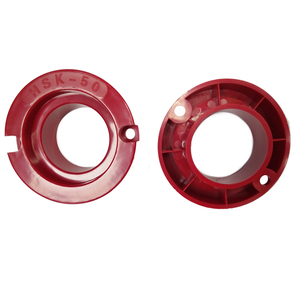

About red chucks

In the sphere of precision manufacturing and metalworking, red chucks refer to a specialized class of clamping devices that secure objects with radial symmetry, particularly during complex milling and cutting tasks. These tools are crucial for maintaining the workpiece's stability and precision throughout machining operations. The moniker red chucks transcends their hue, signifying a spectrum of chucks that are frequently custom-engineered to meet distinct industrial needs.

Types and Characteristics of Red Chucks

Exploring the assortment of red chucks, one encounters various designs tailored to specific machining endeavors. Self-centering chucks automatically position the workpiece at the center, a vital feature for tasks demanding high precision. Independent chucks, conversely, permit individual jaw adjustment, offering adaptability for workpieces of unconventional shapes. Collet chucks, employing a sleeve with a cylindrical interior and a tapered exterior, secure the workpiece with exceptional accuracy and a strong hold, particularly for smaller components. This range of chuck types ensures that there exists a red chuck optimized for efficiency and precision for each unique task.

Structure and Operation of Red Chucks

The architecture of a red chuck is an engineering feat, consisting of several integral parts. The chuck's body acts as the foundation, typically mounted to the spindle of a milling machine. Jaws, which can be either stationary or adjustable, are embedded within the body to clamp the workpiece firmly. The jaws' movements are governed by actuation mechanisms, which may be manual, pneumatic, or hydraulic. For instance, in a self-centering chuck, a scroll gear adjusts all jaws in unison, ensuring even clamping. The collaborative precision of these elements is what renders the chuck effective for its intended application.

Materials and Properties

The selection of materials for red chucks is paramount. Commonly, high-grade steel and stainless steel are chosen for their robustness and resistance to warping. Alloy and carbon steel are favored for their resilience under strenuous conditions, while aluminum offers a lighter option without compromising stability. Carbide, celebrated for its stiffness, is often employed in parts necessitating resistance to wear. These materials are carefully chosen to strike a balance between strength, longevity, and precision in the chuck's performance.

Business Usages and Applications

Red chucks are employed across a broad spectrum of business environments, notably in manufacturing facilities where precision metalworking is of the essence. In the automotive sector, they play a critical role in the production of engine parts. Within the aerospace industry, they are utilized to construct complex components that must meet exacting standards. The versatility of red chucks in accommodating various shapes and sizes makes them invaluable in bespoke manufacturing, significantly enhancing operational efficiency and the caliber of the output.

Functions and Tasks

The fundamental role of a red chuck is to ensure a workpiece is securely positioned while undergoing machining. This task demands high precision, as any minor deviation can lead to a defective product. Red chucks are engineered to facilitate a range of operations, from straightforward drilling to more intricate milling, turning, and grinding. They are also adept at managing swift tool changes, a necessity in high-volume production settings.

Features and Unique Selling Points

Key attributes of red chucks include their sturdy build, precise jaw alignment, and versatile clamping functions. These chucks often boast additional features such as resistance to corrosion and specialized jaw configurations to accommodate diverse workpiece materials. The unique selling proposition of red chucks lies in their amalgamation of durability, precision, and flexibility, distinguishing them from other clamping devices on the market.

Benefits and Positive Outcomes

The adoption of red chucks in machining processes yields numerous advantages. They diminish setup times, enhance machining precision, and prolong the lifespan of machine tools by ensuring a stable and secure grip. The exactitude of red chucks also curtails waste, translating to cost efficiencies and more effective material utilization. For operators, the ease and dependability of red chucks can markedly boost job satisfaction and productivity.

How to Use and Maintain Red Chucks

Optimal use of red chucks commences with their correct installation on the milling machine, confirming that the chuck is precisely centered and tightly secured. When choosing a red chuck, it is crucial to account for the workpieces' dimensions and geometry, as well as the machining operation at hand. Maintenance is straightforward yet vital; chucks should be cleaned of metal filings and debris post-use to preserve accuracy. Routine upkeep involves inspecting for wear, ensuring lubrication of moving parts, and calibrating the chuck periodically to sustain its precision.

Target Audience and Meeting Needs

The intended clientele for red chucks encompasses machinists, manufacturing engineers, and production supervisors in industries like automotive, aerospace, and custom manufacturing. These experts depend on red chucks for their precision, efficiency, and dependability. By grasping the specific demands of these users, red chuck producers can customize their offerings to better meet the preferences and requirements of their market.

What are the key considerations when integrating red chucks into a manufacturing process?

Introducing red chucks into a manufacturing workflow necessitates careful evaluation of their compatibility with milling machines, the nature of the workpieces involved, and the precise operations to be undertaken. It is imperative to match the chuck's specifications with the task's demands to ensure peak performance and accuracy.

How do red chucks contribute to the efficiency and precision of milling operations?

Red chucks significantly bolster the efficiency and precision of milling operations by providing a steadfast and secure hold on the workpiece. This firm anchoring permits higher machining speeds without compromising on accuracy, leading to heightened productivity and diminished operational expenses.

What support and customization options are available for businesses looking to purchase red chucks?

Enterprises in the market for red chucks can avail themselves of a suite of support and customization services. OEM, ODM, and OBM offerings enable the procurement of chucks that conform to specific needs, be it adapting to unique workpiece dimensions, integration with particular milling machines, or alignment with corporate branding.

Explore the extensive array of red chucks on Alibaba.com, crafted to satisfy the stringent demands of contemporary manufacturing and elevate the precision of your milling operations.