Popular in your industry

Top categories

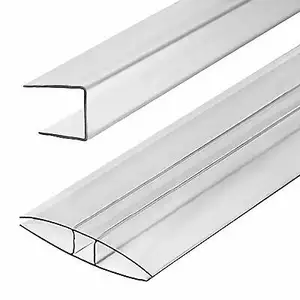

About plastics extrusion profiles

Understanding Plastics Extrusion Profiles

Plastics extrusion profiles are fundamental components in various industries, serving as versatile solutions for finishing, joining, and edging in construction and manufacturing. These profiles are produced through a process where plastic material is melted and formed into a continuous profile that is then cut to length. The adaptability of extruded plastic shapes makes them suitable for a wide range of applications, from window trims to complex industrial parts.

Types and Applications of Extruded Plastic Profiles

The diversity of plastic extrusions is evident in their applications. Rigid PVC profiles, for instance, are sought after for their durability and resistance to deformation, making them ideal for construction purposes where stability is paramount. On the other hand, flexible plastic extrusion profiles are utilized in scenarios requiring adaptability, such as sealing components in the marine industry. Custom plastic extrusion services enable the creation of tailored solutions for specific design challenges, including irregularly shaped spaces where standard profiles may not suffice.

Features and Materials

Extruded profiles plastic materials range from non-recycled to recycled plastics, catering to both budgetary considerations and environmental consciousness. The selection of material impacts the profile's properties, such as flexibility, colorfastness, and weather resistance. For instance, u channel plastic extrusion made from PVC is renowned for its insulation properties and is commonly used to frame windows and doors, providing a seal against drafts.

Advantages of Plastic Extrusion Profiles

The advantages of using plastic profile suppliers extend beyond the variety of shapes and sizes. These profiles offer a cost-effective solution for both protective and aesthetic purposes in construction and manufacturing. They are also lightweight, easy to install, and require minimal maintenance, which contributes to their popularity in various sectors. Additionally, the ability to produce stock extruded plastic profiles ensures that suppliers can meet demand promptly.

Customization and Variety

Customization is a significant aspect of plastic extrusion suppliers, allowing for the production of custom profile extrusion to meet unique requirements. This bespoke production caters to specific industry needs, from simple color variations to complex cross-sectional designs. Furthermore, the availability of extruded PVC shapes in various colors enables integration into different design schemes, enhancing the aesthetic appeal of the end product.

Choosing the Right Supplier

Selecting the right supplier is crucial when sourcing stock plastic extrusion profiles or custom plastic profiles. It is essential to consider the supplier's capacity to provide a consistent supply of profiles that meet the required specifications and quality standards. The platform facilitates connections between buyers and a multitude of suppliers, ensuring a comprehensive range of options for every application.