Popular in your industry

Related Searches:

Top categories

About plastic jar seaming machine

Introduction to Plastic Jar Seaming Machines

Plastic jar seaming machines are essential equipment in the packaging industry, designed to securely seal containers filled with a variety of products. These machines play a pivotal role in ensuring the integrity and shelf-life of items across multiple sectors, from food and beverages to pharmaceuticals and cosmetics. The precision and efficiency of plastic jar seaming machines are critical in maintaining the quality and safety of packaged goods.

Types and Applications

There are several types of plastic jar seaming machines, each tailored to accommodate different sizes, shapes, and sealing requirements. The versatility of these machines allows them to be employed in diverse fields, ensuring that whether the container holds a liquid, powder, or spray, the seal is secure and reliable. The application of these machines spans industries, reinforcing the value they bring to various packaging processes.

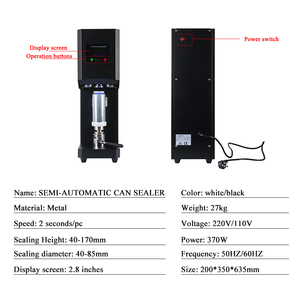

Features and Materials

The construction of plastic jar seaming machines involves robust materials that contribute to their longevity and reliability. These machines are engineered to handle the demands of continuous operation, with features that promote ease of use and consistency in sealing. The adaptability of seaming machines to different materials and container types is a testament to their advanced design.

Advantages of Modern Seaming Technology

Modern plastic jar seaming machines are equipped with technology that enhances their performance. The benefits of using these advanced machines include improved seal integrity and faster processing times, which contribute to higher productivity levels. Additionally, the precision of modern seaming machines minimizes waste, making the packaging process more sustainable.

Ensuring Quality and Safety

Quality assurance is paramount when it comes to plastic jar seaming machines. These machines undergo rigorous testing to ensure they meet industry standards for strength and durability. The seals they produce are checked against stringent test methods to confirm their resilience under various conditions, such as pressure and temperature fluctuations.

Choosing the Right Machine

Selecting the appropriate plastic jar seaming machine requires a thorough analysis of its features and the specific needs of the application. Factors such as container size, material compatibility, and desired throughput should guide the decision-making process. While Alibaba.com hosts a wide array of machines, it is crucial to match the right machine to the intended use to ensure optimal performance.