Introduction to Plastic Film Grinders

Plastic film grinders are essential equipment in the recycling process, designed to shred and grind down plastic film into smaller pieces for easier processing and recycling. These machines are robust and efficient, catering to a variety of plastic films including polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC).

Types and Configurations

There are several types of plastic film grinders, each suited to specific needs and applications. From heavy-duty granulators to smaller units for in-house operations, the range includes in-line grinders for thermoforming operations, beside-the-press versions for immediate recycling of scrap, and centralized models for large-scale recycling tasks.

Applications and Uses

Plastic film grinders play a pivotal role in recycling plants and in-house production facilities. They are used to process post-industrial waste, agricultural films, and post-consumer bags. By converting bulky film into flakes or regrind, these machines facilitate the reuse of plastic material, contributing to a circular economy and reducing environmental impact.

Features and Materials

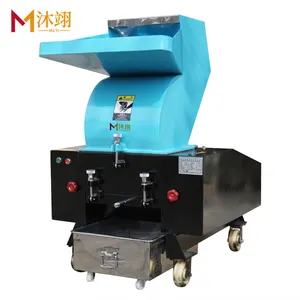

Constructed from durable materials, plastic film grinders are built to withstand the rigors of continuous operation. They feature cutting chambers, high-torque motors, and are equipped with screens to control particle size. The design of the rotor, blades, and chamber ensures efficient grinding with minimal dust and noise.

Advantages of Utilizing Plastic Film Grinders

Utilizing a plastic film grinder offers numerous advantages such as reducing the volume of waste, improving the logistics of recycling, and creating a valuable resource from waste material. These machines are also designed to be energy-efficient, reducing operational costs while maximizing output.

Environmental Impact and Sustainability

The use of plastic film grinders significantly contributes to environmental sustainability. By recycling plastic films, these machines help in reducing the reliance on virgin materials, lowering greenhouse gas emissions, and minimizing the amount of waste sent to landfills.

plastic film grinder

recycling process

polyethylene (PE)

granulators

circular economy

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4