Popular in your industry

Related Searches:

Top categories

About phenolic resin binder

Introduction to Phenolic Resin Binder

Phenolic resin binders are a class of synthetic polymers obtained by the reaction of phenol or substituted phenol with an aldehyde. Known for their excellent adhesive properties and thermal stability, these binders are essential in various industrial applications. This introduction delves into the properties, types, and uses of phenolic resin binder, providing insights into their significance in commercial sectors.

Types and Applications

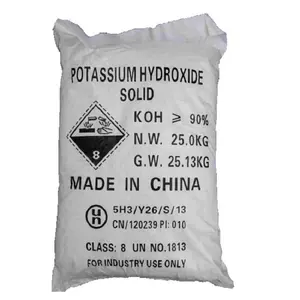

The versatility of phenolic binder types ranges from alkaline phenolic resin binder to phenolic urethane resin, each serving specific industrial needs. Alkaline phenolic resin binders are often utilized in foundry core and mold applications due to their superior shakeout and collapsibility. On the other hand, phenolic urethane resins are favored in the manufacturing of abrasives, friction materials, and insulation due to their toughness and heat resistance. These binders find their place in the garment industry, construction, and the production of ceramics and tiles.

Features and Material Composition

Phenolic resin binders are composed of materials such as silicone, polysiloxane, and various fillers and tackifiers. These components contribute to the binder's ability to withstand harsh conditions, making them suitable for use where durability is paramount. The material composition ensures that the binders offer UV protection and hydrolysis resistance, enhancing their performance in outdoor and moisture-prone environments.

Advantages of Phenolic Resin Binders

The advantages of using phenolic resin binder are manifold. Their resistance to high temperatures and weather elements makes them an ideal choice for outdoor applications. Additionally, their capacity to prevent corrosion on metals and their waterproof nature extend their usability across various industries. The efficacy of these binders in bonding materials together firmly is matched by their ease of use and extended shelf life, ensuring they remain a practical option for professionals.

Environmental and Safety Considerations

Safety and environmental considerations are paramount when dealing with industrial materials. Phenolic resin binders are formulated to be safe for use, with considerations for the user's health and environmental impact. While handling these substances, it is crucial to follow appropriate safety guidelines to mitigate any potential risks associated with their use.

Choosing the Right Phenolic Resin Binder

Selecting the appropriate phenolic resin binder depends on the specific requirements of the task at hand. Factors such as the desired consistency, efficacy, and the material to be bonded are crucial in determining the most suitable binder. While Alibaba.com hosts a range of options, it is essential to assess the product specifications to ensure they align with the intended application.