Understanding Material FR2 PCB

The term material FR2 PCB refers to a specific type of printed circuit board (PCB) that utilizes flame retardant level 2 (FR2) material. This category of PCB is known for its cost-effectiveness and is primarily used in consumer electronics. The FR2 material is a composite of paper and phenolic resin, which offers a balance between functionality and affordability.

Types and Applications of FR2 PCB

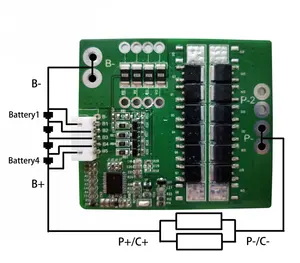

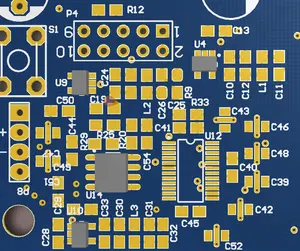

FR1 FR2 FR3 FR4 are classifications that denote the flame retardancy of the PCB material, with FR2 being a widely chosen option for less demanding applications. The fr2 pcb material is suitable for single-layer boards and is commonly found in household electronics due to its sufficient electrical insulating properties and adequate durability for low-power devices.

Features of FR2 PCB Material

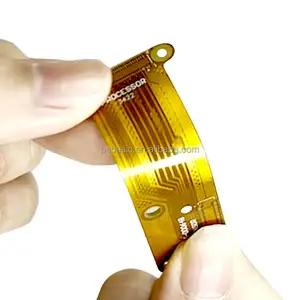

The fr 2 pcb is characterized by its distinctive brownish color and is known for its good punching properties, making it suitable for through-hole components. It is not as robust as higher classifications like FR4 but is a practical choice for applications where extreme temperatures and high performance are not critical. The material's properties include moderate thermal resistance and mechanical strength.

Advantages of Using FR2 PCB

Choosing material fr2 pcb offers several advantages, such as cost efficiency and ease of manufacturing, which can be particularly beneficial for bulk production. Its insulating properties are sufficient for a variety of low-power applications, and its flame retardant nature ensures a degree of safety in consumer products. However, it is essential to match the material properties with the intended use of the PCB to ensure reliability.

Materials and Manufacturing Processes

The manufacturing process of fr2 pcb material involves pressing layers of paper impregnated with phenolic resin to create a rigid, durable board. This process is less complex than that of higher-grade materials, which contributes to the lower cost of FR2 PCBs. The material's ease of handling and machining also allows for a more streamlined production process.

Selection Criteria for FR2 PCB

When selecting an fr 2 pcb, it is crucial to consider the electrical requirements of the application, the environmental conditions it will be subjected to, and the mechanical stresses it may encounter. While FR2 PCBs are not suitable for high-performance or high-temperature environments, they are an excellent choice for many consumer electronics where these conditions are not a concern.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4