Popular in your industry

Related Searches:

Top categories

About machine assembly line

Introduction to Machine Assembly Line

A machine assembly line is a system of machines, tools, and workers arranged in a continuous sequence to assemble a product. It is a crucial component in manufacturing industries for mass production. The assembly line allows for efficient production, increased output, and standardized product quality.

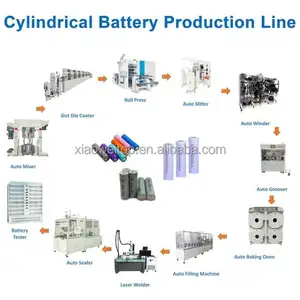

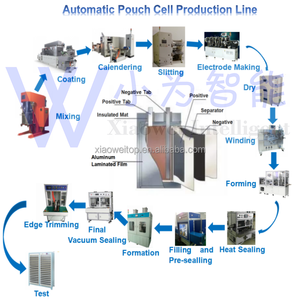

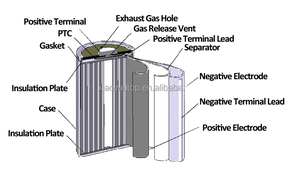

Types of Assembly Line Equipment

There are various types of assembly line equipment used in machine assembly lines. These include conveyor belts, robotic arms, screwdriving machines, welding tools, and quality control systems. Each type of equipment plays a specific role in the assembly process, ensuring smooth workflow and high precision.

Technical Details of Machine Assembly Line

A machine assembly line typically consists of multiple stations where different components are added to the product. The line is designed to maximize efficiency by reducing downtime between tasks. The equipment used in the assembly line is often automated to speed up the production process and minimize errors.

Advantages of Using Assembly Line Machine

The assembly line machine offers several advantages to manufacturers. It increases productivity by streamlining the production process, reduces labor costs by automating repetitive tasks, improves product quality through standardized assembly procedures, and allows for scalability to meet growing demand.

Key Features of Machine Assembly Line

Modern machine assembly lines are equipped with advanced features such as real-time monitoring systems, integration with IoT technology for data analytics, and flexible configurations to accommodate different product variations. These features help manufacturers optimize their production processes and adapt to changing market demands.

When choosing a machine assembly line, consider factors such as the production volume, product complexity, required flexibility, and budget constraints. It is essential to select equipment that meets your specific manufacturing needs and can be easily integrated into your existing production setup.

Regular maintenance of the assembly line machine is crucial to ensure optimal performance and longevity. This includes routine inspections, cleaning of equipment, lubrication of moving parts, and timely replacement of worn-out components. Following a maintenance schedule can prevent unexpected breakdowns and production disruptions.

In conclusion, investing in a machine assembly line can revolutionize your manufacturing process by enhancing efficiency, productivity, and product quality. By understanding the technical details, advantages, and key features of assembly line machines, you can make informed decisions to optimize your production operations and stay competitive in the market.