Popular in your industry

Related Searches:

Top categories

About lightweight concrete panels

What are Concrete Panels For Lightweight Construction

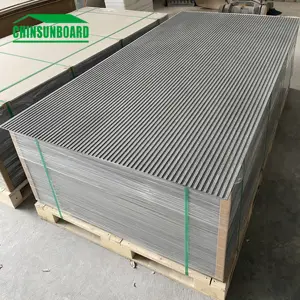

Concrete panels for lightweight construction are a modern building material that offer a range of advantages over traditional concrete blocks and other building materials. These panels are typically made from a combination of cement, sand, and lightweight aggregates, such as pumice or perlite. The result is a strong yet lighter concrete product that is particularly well-suited for various types of construction projects, including residential, commercial, and industrial applications.

The principle behind using concrete panels for lightweight construction lies in their reduced weight compared to standard concrete elements. This feature makes them easier to transport, handle, and install, thereby contributing to faster construction times and cost savings. Additionally, their lighter weight minimizes the load on building foundations and walls, potentially leading to lower material and labor costs.

Concrete panels for lightweight construction also come with the benefit of providing excellent thermal insulation and soundproofing properties. Their composition allows for a versatile finish, which can be painted, plastered, or left bare, depending on the aesthetic requirements. Their use is not limited to creating walls; they can also be used for flooring systems, roofs, and as structural elements in buildings.

Types of Concrete Panels for Lightweight Construction

Lightweight concrete panels come in various types to cater to different construction needs and applications. Here is an overview of some common types:

-

Foamed Concrete Panels: These panels are made by incorporating foam into the concrete mix. The foam acts as a void-forming agent, creating air pockets that lighten the weight of the concrete. They are often used in floors, roofs, and walls for thermal and sound insulation purposes.

-

Precast Concrete Panels: These are pre-made panels that are manufactured off-site and then installed on-site. They can be used for both structural and non-structural elements in buildings such as exterior walls, interior walls, or flooring.

-

Composite Concrete Panels: Made from a combination of concrete and other materials like polystyrene or metal, these panels offer a high strength-to-weight ratio. They are frequently used in commercial and industrial buildings for flooring and as walling systems.

-

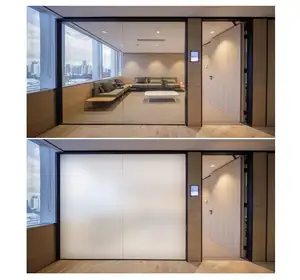

Sandwich Panels: Consisting of an insulating core sandwiched between two layers of concrete, these panels provide excellent thermal insulation properties. They are commonly used for exterior walls in all types of buildings.

-

Hebel Panels: These are large lightweight panels made from autoclaved aerated concrete (AAC) which contains a significant amount of air voids. Hebel panels are often used for interior walls, partitions, and flooring.

How to choose Concrete Panels For Lightweight Construction

Selecting the right concrete panels for a lightweight construction project requires careful consideration of several factors. Businesses involved in such projects should assess the specific needs of their application, especially in terms of performance characteristics like fire resistance, soundproofing, and thermal insulation.

Firstly, consider the application environment—will the panels be used for exterior walls, interior walls, or as part of a flooring system? This will determine the required durability and resistance properties such as impact strength or moisture protection.

Secondly, design style matters significantly as it should complement the overall architectural theme. Whether it's for a modern office building or a traditional villa, there are concrete panels available in various colors, textures, and styles that can achieve the desired aesthetic while ensuring structural integrity.

The local service location is also crucial for logistical reasons; sourcing from suppliers within close proximity can reduce transportation costs and ensure that the panels meet local building codes and regulations.

Additionally, it's important to consider the core components like motors or gears if the project involves machinery test report provided by the suppliers. Understanding after-sale services available such as onsite installation support or inspection can also be beneficial for ensuring seamless project completion.

About Concrete Panels For Lightweight Construction on Alibaba.com

Alibaba.com stands as a global wholesale marketplace that connects businesses with a vast selection of concrete panels suitable for various construction applications. With over two decades of experience facilitating B2B transactions across over 190 countries, Alibaba.com has established itself as a platform that offers an extensive array of building materials from reputable suppliers.

The diversity of options available on Alibaba.com ensures that businesses can find exactly what they need to complete their construction projects. Whether it's lightweight panels for interior decorations or durable sandwich panels for external walls, Alibaba.com lists products that adhere to high standards of quality and design. Furthermore, with features like Trade Assurance, businesses can shop with confidence knowing that their payments are protected until delivery is completed.

Alibaba.com's commitment to helping small and medium-sized enterprises thrive is evident through its user-friendly mobile buying options and local language communication tools. By providing access to an international network of suppliers who offer customizable solutions for specific project needs without compromising on quality or service reliability, Alibaba.com has become an indispensable resource for businesses looking to source construction materials efficiently and affordably.

Common FAQs for Concrete Panels For Lightweight Construction

What are the primary benefits of using concrete panels for construction?

Concrete panels offer high strength, durability, and resistance to various environmental conditions. They also provide efficient thermal and acoustic insulation, which can contribute to energy savings and a more comfortable interior environment.

How do the thermal properties of concrete panels contribute to energy efficiency?

The thermal properties of concrete panels, including high thermal mass and inherent thermal insulation, help to regulate indoor temperatures, reducing the need for excessive heating or cooling systems and thereby contributing to energy efficiency.

Can concrete panels be customized in terms of size and shape?

Yes, concrete panels can be customized to specific sizes and shapes to fit the requirements of different projects. Suppliers on Alibaba.com often offer design assistance and project solution capabilities to meet unique project specifications.

Are there any limitations on where concrete panels can be used?

While concrete panels can be used in a wide range of applications, they should be assessed for their structural capabilities and suitability for the intended location, such as load-bearing walls for high-rise buildings or facade panels for decorative purposes.

How do I determine the right type of concrete panel for my project?

The choice of concrete panel depends on factors like project location, intended use (structural or aesthetic), core material (for thermal or acoustic purposes), local climate conditions, and design requirements. Suppliers can provide guidance on the most suitable type for your application.

Are there eco-friendly options available for concrete panels?

Eco-friendly options for concrete panels include panels made from recycled materials or those with eco-friendly certifications. Suppliers on Alibaba.com may offer panels with features like low toxicity or high energy efficiency.

What is the expected lifespan of concrete panels in construction projects?

Concrete panels have a long lifespan, often exceeding 50 years when properly maintained. Their durability makes them a suitable choice for structures that require longevity.

How do I ensure the quality of concrete panels when purchasing in bulk?

When purchasing in bulk, you can request samples, check supplier ratings and reviews on Alibaba.com, and use services like Trade Assurance to ensure the quality of your order.

Can concrete panels be used for both interior and exterior applications?

Yes, concrete panels are versatile and can be used for both interior and exterior applications. For exterior use, it's essential to choose panels that are designed for weather resistance and have appropriate surface treatments.

What maintenance is required for concrete panels after installation?

Maintenance for concrete panels typically involves regular cleaning to remove debris and prevent staining. Some may also require periodic inspections for structural integrity, depending on their design and the local climate.

How do I choose between different types of core materials for concrete panels?

Core material choice affects the panel's properties such as thermal insulation, sound absorption, and fire resistance. Carefully consider these factors against your project's specific needs.

What after-sale services are typically provided with the purchase of concrete panels?

After-sale services for concrete panels may include onsite installation, training, technical support, and provision of spare parts. Availability varies by supplier.

How can I ensure rapid installation of concrete panels on my project site?

To ensure rapid installation of concrete panels, consider choosing lighter core materials and opting for systems with simple interlocking or assembly mechanisms.