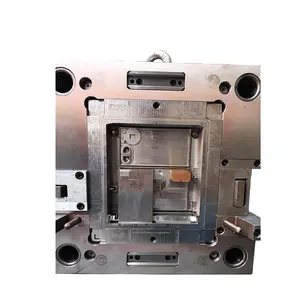

Introduction to Injection Moulding for Plastic Waste Bins

Injection moulding is a pivotal manufacturing process for producing plastic waste bins, a category that encompasses a variety of bins designed for waste collection and management. This process involves injecting molten plastic into a mould to create products with high precision and repeatability. The versatility of injection moulding for plastic waste bin production allows for a wide range of designs, catering to diverse applications from office spaces to industrial environments.

Types and Applications

The types of plastic waste bins produced through injection moulding vary in size, shape, and functionality. They range from small desk-side bins to large commercial-grade containers. The applications are equally diverse, with bins specifically designed for recyclables, organic waste, or general trash. The adaptability of the injection moulding process ensures that bins meet the specific needs of waste segregation and storage.

Material Considerations in Moulding

Material selection is critical in the production of plastic waste bins. Common materials include polyethylene (PE) and polypropylene (PP), known for their durability and recyclability. The choice of material affects the bin's strength, flexibility, and resistance to chemicals or UV light. Injection moulding allows for the use of recycled plastics, contributing to sustainability efforts in the production of plastic waste containers.

Features and Advantages of Injection Moulded Bins

Injection moulded plastic waste bins offer several features, such as resistance to impact, ease of cleaning, and the ability to withstand various environmental conditions. The precision of injection moulding results in consistent quality and fit, essential for bins that may be part of larger waste management systems. The efficiency of the process often leads to cost-effectiveness in large-scale production, making plastic waste bin manufacturing more accessible and affordable.

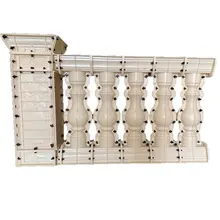

Customization and Standardization

While customization is a significant advantage of injection moulding, standardization within the production of plastic waste bins can further enhance efficiency. Standardizing elements such as lift bars, connection sizes, and clamp slots can simplify the manufacturing process and interchangeability. This approach benefits suppliers and buyers on Alibaba.com, facilitating the sourcing of compatible components and streamlining inventory management for plastic waste bin suppliers.

Choosing the Right Injection Moulding Service

Selecting the appropriate service for injection moulding for plastic waste bin production is crucial. Alibaba.com hosts a multitude of suppliers, each with the capability to produce bins that align with specific requirements. Prospective buyers can evaluate the expertise of suppliers, considering factors such as material knowledge, design capability, and production capacity. This careful selection ensures that the final product meets the desired specifications and application needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4