Understanding Hydraulic Rock Breaker Chisels

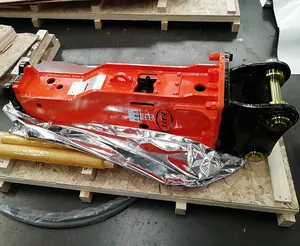

Hydraulic rock breaker chisels are essential tools in the construction and mining industries, designed for breaking through rock, concrete, and other hard materials. These robust tools are engineered to withstand the rigors of heavy-duty work, with a focus on efficiency and durability.

Design and Construction

The construction of hydraulic rock breaker chisels involves advanced technology to ensure they meet the demands of tough working conditions. The chisels are housed in a protective casing that not only shields the power cell from external damage but also significantly reduces operational noise. This casing is instrumental in preventing the ingress of dust and debris, which could otherwise impair the breaker's performance.

Features and Performance

A standout feature of these chisels is their vibration-dampening suspensions, which serve to enhance operator comfort by reducing the amount of vibration transmitted. Additionally, the ability to adjust the hammer's stroke allows for tailored operation according to the task at hand. The integration of auto-adjusting impact mechanisms enables the chisel to automatically calibrate its impact force and frequency to match the hardness of the material being worked on, optimizing performance and reducing wear on the equipment.

Technology Integration

Modern hydraulic rock breaker chisels are equipped with auto-speed technology, which detects changes in material hardness and adjusts the impact energy and striking rate accordingly. This not only improves efficiency but also minimizes the recoil energy transferred back to the excavator or carrier, thereby enhancing the longevity of the breaker. Another technological advancement in these tools is the blank-fire protection, which employs a hydraulic cushion at the base of the cylinder bore to mitigate the movement of the piston and prevent metal-to-metal contact, reducing the risk of premature wear.

Advantages of Advanced Features

The incorporation of such features in hydraulic rock breaker chisels translates to a notable increase in productivity. The reduced vibration and automatic adjustments lead to a more comfortable and less fatiguing experience for the operator, which can result in longer working periods and greater efficiency on the job site. The blank-fire protection not only extends the life of the chisel but also ensures consistent performance, which is crucial for project timelines and cost management.

Selection Considerations

When selecting a hydraulic rock breaker chisel, it is important to consider the specific requirements of the job and the compatibility with the carrier. Factors such as the material to be broken, the size of the carrier, and the desired outcome should guide the selection process. While Alibaba.com does not endorse any particular brand or make guarantees, the platform offers a diverse range of options to suit various operational needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4