DIN rail cutting machine has revolutionized the way electrical installers cut rails. Using a DIN rail cutter has made the process more efficient, accurate, and faster.

What is a DIN rail cutter?

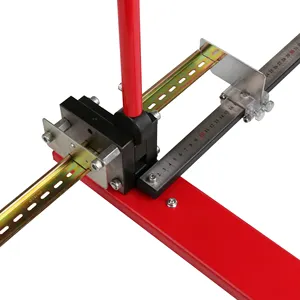

DIN rail cutters are specialized tools designed to cut DIN rails to the required length. DIN stands for Deutsches Institut für Normung, which translates to the German Institute for Standardization. DIN is a standard used in various industries, including electrical engineering. DIN rails are metal rails that mount electrical equipment inside a control panel or enclosure. They are usually used in industrial and commercial applications. DIN rails are designed to be compatible with various types of electrical components, making them a popular choice for electrical installations. DIN rail cutters are commonly used in electrical installations, particularly in industrial settings. A rail cutter is handy in applications that require precision cutting, such as control systems, power distribution systems, and automation systems. These tools are essential for cutting DIN rails to size and ensuring they fit nicely inside the electrical panel. They are also used for cutting rails to specific lengths and angles, allowing installers to create custom configurations for different applications. TheDIN rail cutting tool is designed to be used efficiently and requires little training.

Advantages of a DIN rail cutter

DIN rail cutters offer several advantages for electrical installers. First, these tools are designed for precision cutting, ensuring the rails fit nicely inside the electrical panel. The precise cuts also reduce the risk of gaps between the rails, which can lead to loose connections and safety hazards. Second, the hydraulic DIN rail cutter efficiently cuts multiple rails simultaneously. This feature saves time and increases productivity, allowing installers to complete projects quickly and with less labor. Additionally, the tool's efficiency minimizes material waste, reducing costs associated with purchasing and replacing materials. Third, DIN rail cutters are designed to be durable and long-lasting. They are made from materials that can withstand heavy use and regular wear and tear. This durability reduces the need for frequent replacement. Finally, DIN rail cutters are versatile and can cut rails from different materials, including steel, aluminum, and copper. This feature allows installers to work with various materials and sizes, making the tool an essential asset for electrical installations.

In summary, DIN rail cutters offer several advantages for electrical installers, including precision cutting, efficiency, durability, and versatility. These features make the tool an essential asset for electrical installations, helping installers to complete projects faster, with greater precision, and at lower costs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4