Popular in your industry

Top categories

About cutting mold

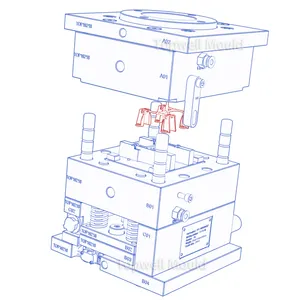

Understanding Cutting Molds

Cutting molds are essential tools in the manufacturing sector, enabling the precise shaping of materials for a myriad of applications. This category encompasses a variety of molds designed for cutting intricate designs and patterns, such as cutting crown molding and cutting baseboards. These molds are crafted to meet the specific needs of production, whether for large-scale industrial use or more detailed custom work.

Types and Applications of Cutting Molds

The diversity of cutting molds is evident in their applications, ranging from coping crown molding to creating detailed baseboard corner cuts. Injection molds are particularly popular for producing small, complex items, while larger designs may utilize molds for decorative purposes, such as those used in cutting corners for baseboards. The application of these molds spans various industries, from construction to consumer goods, highlighting their versatility.

Features and Materials

Cutting molds are available in various materials, including iron and composites, to suit different manufacturing requirements and material characteristics. The choice of material affects the mold's durability and the finish quality of the cut product. For instance, cut base molding requires a mold that can deliver a clean cut without compromising the material's integrity. Similarly, cutting crown molding inside corners demands precision, which is directly influenced by the mold's material and design.

Advantages of Precision Molds

The advantages of using precision cutting molds are numerous. They ensure repeatability and consistency in production, which is crucial for maintaining standards. Moreover, the ability to standardize certain elements, like lift bars and clamp slots, can significantly reduce production costs and increase efficiency. This standardization is particularly beneficial when dealing with complex patterns such as coping cut crown molding or cutting inside corners on crown moulding.

Selection and Customization

Selecting the right cutting mold involves considering the design, material, and the specific requirements of the product. Suppliers on Alibaba.com offer a range of customization options to ensure that the mold meets the precise needs of the buyer. This includes creating test samples to ensure that the mold produces the desired outcome, such as achieving the perfect inside corner cut for crown molding.

Optimizing Production with Cutting Molds

In conclusion, cutting molds are a critical component in the manufacturing process, offering precision and efficiency. Alibaba.com serves as a platform where buyers can connect with expert suppliers to find the right mold solutions, such as those for coped trim or intricate inside corner cut crown molding. By leveraging the detailed information provided by suppliers, buyers can make informed decisions to optimize their production processes with the appropriate cutting molds.