Popular in your industry

Related Searches:

Top categories

About crucible for lead

Exploring the Versatility of Lead Crucibles

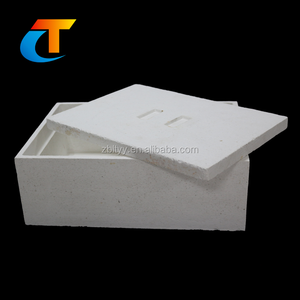

Lead processing requires specialized equipment, and a crucible for lead is at the heart of this operation. These containers are designed to withstand the high temperatures needed to melt and cast lead and its alloys. The durability and resistance to thermal shock make lead crucibles an essential tool for metallurgists and craftsmen alike.

Types and Applications of Lead Crucibles

The crucible for melting lead comes in various sizes and shapes, catering to a wide range of industrial and artisanal applications. From small-scale laboratories to large foundries, the selection of a crucible is critical. The capacity of these crucibles can range from as little as 1kg to over 500kgs, accommodating different scales of lead processing tasks. Their use extends beyond simple melting, serving crucial roles in purification and alloy creation.

Features and Materials

A crucible lead is typically fashioned from graphite due to its excellent thermal conductivity and chemical inertness. Graphite crucibles are favored for their ability to handle extreme temperatures without degrading. The material's resilience against oxidation is a key feature, particularly when dealing with molten metals that may otherwise corrode lesser materials. The construction of these crucibles often includes resin bonds and a high density of graphite, enhancing their longevity and performance.

Advantages of Using a Crucible for Lead

Utilizing a crucible for lead offers several advantages. The high thermal conductivity of graphite ensures even heat distribution, reducing the risk of hot spots and promoting uniform melting. This efficiency can lead to energy savings and a reduction in processing time. Moreover, the robust nature of graphite crucibles means they can be used repeatedly, providing an economical choice for continuous operations. Their compatibility with various metals and non-metal oxides also makes them versatile tools in a metallurgist's arsenal.

Environmental Considerations

In an era where environmental impact is a growing concern, the use of graphite crucibles is a step towards responsible manufacturing. Their longevity and efficiency contribute to less waste and lower energy consumption. The reduced need for frequent replacements also means less material ends up in landfills, making crucible for lead a more sustainable option in metal processing industries.

Choosing the Right Crucible on Alibaba.com

Alibaba.com hosts a diverse array of crucibles suitable for various lead-related tasks. Whether for use in medium frequency furnaces or for handling non-metal oxides, the platform connects buyers with a multitude of suppliers to find the right crucible for their specific needs. With no minimum order requirements, both small and large scale operations can source the appropriate crucible for lead without the constraint of order size, ensuring that every project requirement is met with precision.