Popular in your industry

Related Searches:

Top categories

About chair shell mould

Exploring Chair Shell Moulds

The realm of furniture manufacturing is ever-evolving, with chair shell moulds standing as a testament to the innovation in this industry. These moulds are pivotal in crafting the ergonomic and aesthetic components of chairs, which are integral to both residential and commercial spaces. The chair shell serves as the backbone of chair design, dictating comfort, style, and durability.

Types and Applications

There is a diverse array of chair shell moulds to cater to various applications. From sleek office chairs to robust dining room seating, the moulds vary significantly. They are employed in creating chair shells for educational institutions, healthcare facilities, and hospitality venues, among others. The adaptability of these moulds allows for customization in line with functional requirements and design preferences.

Material Insights

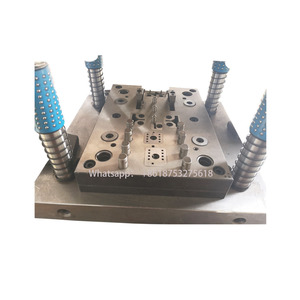

Materials used in chair shell moulds are chosen for their resilience and molding capabilities. Common materials include metals and advanced polymers, each offering distinct advantages in terms of strength and finish. The selection of material impacts the mould's longevity and the quality of the chair shells produced, making it a critical consideration in the manufacturing process.

Features and Advantages

Chair shell moulds are designed with precision, ensuring that each chair shell has consistent quality and conforms to ergonomic standards. The advantage of using these moulds lies in their ability to produce chair shells en masse, which is essential for meeting the demands of large-scale production without compromising on quality. Furthermore, the reusability of these moulds presents an economical solution for manufacturers.

Optimizing Production with Chair Shell Moulds

Optimization of production is achievable through the standardization of certain mould elements. By harmonizing aspects like lift bars and clamp slots, manufacturers can streamline the production process, enhancing efficiency and reducing the need for multiple adjustments. This standardization also facilitates the interchangeability of parts, which is beneficial for maintenance and production flow.

Choosing the Right Mould

Selecting the appropriate chair shell mould is crucial for any furniture production line. It involves assessing the compatibility of the mould with the intended design and material. Suppliers on Alibaba.com offer a variety of moulds, each capable of producing chair shells that meet specific industry standards. It is essential to engage with suppliers to ensure that the mould aligns with the production goals and yields satisfactory outcomes.

Incorporating injection moulding techniques, manufacturers can achieve intricate designs with high precision. The versatility of plastic chair moulds allows for a wide range of textures and finishes, enhancing the aesthetic appeal of the chairs. For those seeking sustainable options, eco-friendly moulds are also available, which support the production of environmentally conscious furniture. Lastly, the use of advanced moulding technology ensures that the chair shells are produced with accuracy and consistency, which is paramount in maintaining a competitive edge in the market.