Popular in your industry

Related Searches:

Top categories

About casting machine for plastic

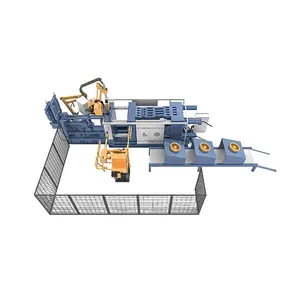

Introduction to Plastic Casting Machines

Casting machines for plastic are integral to the manufacturing sector, providing the essential service of shaping molten plastic into predetermined designs. These machines operate by employing a die to cast the plastic into various forms and sizes, catering to a multitude of industrial applications. From intricate components to large, robust items, the versatility of these machines is pivotal in production lines.

Types and Applications

The landscape of plastic casting machines is diverse, with each type serving a specific function. Injection machine moulding units are prevalent for their efficiency in mass-producing plastic parts. Machine injection moulding and automatic plastic injection moulding machines are sought after for their automation, which streamlines the production process. For specialized tasks, auto injection moulding machines offer precision in the manufacturing of complex designs. The adaptability of these machines allows for their use in various industries, including automotive, healthcare, and consumer goods.

Features and Materials

Modern plastic injection moulding machines are engineered to handle a spectrum of plastic types, ranging from thermosetting polymers to thermoplastics. The construction of these machines focuses on durability and efficiency, with components designed to withstand the high-pressure environment of plastic casting. Innovations in this field have led to the development of new injection moulding machines that enhance production capabilities while maintaining precision.

Advantages of Advanced Machinery

The evolution of plastic die casting machines has brought forth significant advantages. Enhanced speed and precision in the casting process lead to increased productivity and reduced waste. The automation features in automatic plastic injection moulding machines minimize the need for manual intervention, thus optimizing the manufacturing cycle and reducing labor costs.

Choosing the Right Machine

Selecting the appropriate casting machine for plastic requires an understanding of the specific production needs. Factors such as size, power, and capacity must be considered to ensure the machine aligns with the intended applications. Suppliers on Alibaba.com offer a range of options, each with detailed specifications to aid buyers in making an informed decision.

Supplier Engagement and Machinery Acquisition

Engaging with suppliers for a plastic casting machine on Alibaba.com is streamlined to facilitate ease of communication and transaction. Prospective buyers can request information and quotes for machinery that aligns with their operational requirements, ensuring a match that is conducive to their production goals. The platform's extensive inventory includes both new and pre-owned machines, providing options for businesses of all sizes.