Popular in your industry

Related Searches:

Top categories

About braid machines and braider

Braiding Machines and Braiders: An Overview

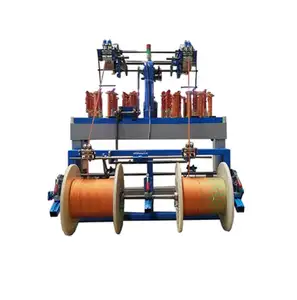

Braiding machines and braiders are essential tools in the textile and cable manufacturing industries. These machines intricately interweave strands of material to produce a variety of braided products. The versatility of braiding machines extends to creating durable laces, ropes, and even specialized cables. With a focus on the industrial sector, these machines cater to a broad spectrum of manufacturing needs.

Types of Braiding Machines

The market offers a diverse range of braiding equipment, each designed for specific applications. The maypole braiding machine, for instance, is commonly used for cable sheathing due to its efficiency in handling complex braiding tasks. For those in the electrical industry, the cable braiding machine is engineered to construct robust cables that withstand various environmental stresses. In the realm of textiles, the yarn braider stands out, weaving fibers into strong yarns suitable for multiple uses, from fashion to industrial applications.

Applications and Features

Braiding machines are not limited to a single function; they are instrumental in producing sports equipment, marine ropes, and even medical-grade materials. The medical braiding machine is a prime example, designed to meet the stringent standards of medical product manufacturing. On the other hand, the rope braiding machine is tailored for creating high-strength ropes used in various sectors, including marine, climbing, and safety equipment.

Materials and Advantages

The materials used in braiding can range from natural fibers to synthetic and metallic wires, such as those used in a copper wire braiding machine. The advantage of using advanced braiders like the herzog braider lies in their precision and the durability of the braids they produce. These machines are designed to handle different materials, ensuring that the end product meets the required strength and flexibility standards.

Choosing the Right Braiding Machine

Selecting the appropriate braiding machine involves considering various factors such as yarn throughput, gear speeds, and power ratings. For instance, a 16 carrier braiding machine might be ideal for complex braiding patterns and high production volumes. Prospective buyers can filter through an extensive listing to find the machine that matches their industrial requirements, without the hassle of navigating through irrelevant options.

Conclusion

In conclusion, the array of braiding machines and braiders available caters to a multitude of industrial needs, from crafting resilient textiles to engineering high-performance cables. The right braiding solution is pivotal for businesses looking to enhance their production with efficiency and reliability. While exploring the vast selections, it is crucial to consider the specific applications and features that align with the manufacturing goals.