Introduction to Battery COS Machines

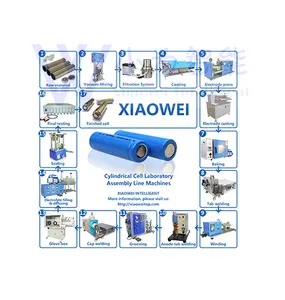

Battery COS (Cell-Oriented Systems) machines represent a specialized category of equipment designed for the automation of battery manufacturing processes. These machines are integral to the production of batteries, ensuring consistency and efficiency in the assembly of battery cells. The technology behind battery cos machine products is engineered to meet the diverse needs of the battery production industry, catering to various scales of operation and material requirements.

Types and Applications

The range of cos machine battery equipment varies from manual liquid fillers, which are ideal for small-scale operations, to semi- and fully-automatic systems suitable for larger production demands. The application of these machines spans across multiple industries, from automotive battery assembly to energy storage solutions. Semi-automatic and fully-automatic battery cos machine options enhance production capabilities, allowing for higher throughput and precision.

Features and Materials

Battery cos machine units are designed with various features to handle different materials and product specifications. For instance, powder fillers are tailored to manage free-flowing substances such as sugar or salt, as well as fine powders used in cosmetics and chemicals. Vibratory weigh fillers are often employed for their precision in handling certain powdery substances. In contrast, high-viscosity materials like creams and gels require the use of positive displacement pump fillers, demonstrating the versatility of cos machine battery technology.

Advantages of Battery COS Machines

The advantages of utilizing a cos machine battery system include enhanced precision and speed in production lines, contributing to overall efficiency. The adaptability of these machines to different substances and their ability to cater to both small and large-scale operations make them a valuable asset in the battery manufacturing sector. Moreover, the automation capabilities of semi- and fully-automatic systems significantly reduce manual labor and potential errors, ensuring a more streamlined production process.

Choosing the Right Battery COS Machine

Selecting the appropriate battery cos machine is crucial for optimizing production efficiency. Factors to consider include the scale of operations, the type of materials being processed, and the desired level of automation. It is important to assess the specific needs of your industry, whether it be in material handling, machine tools, or woodworking, to find a suitable battery cos machine that aligns with your production requirements.

Conclusion

In conclusion, the battery cos machine category encompasses a broad spectrum of machinery designed to meet the intricate demands of battery production. From manual to fully-automatic systems, these machines offer solutions that can enhance the efficiency and precision of manufacturing processes. When considering a cos machine battery for your operations, it is essential to evaluate the specific needs of your industry to ensure you select the most appropriate equipment.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4