Popular in your industry

Related Searches:

Top categories

About automatic smd soldering machine

Exploring Automatic SMD Soldering Systems

Automatic SMD Soldering Systems are advanced machines engineered to execute the delicate task of soldering Surface Mount Devices (SMDs) onto printed circuit boards (PCBs). These components are crucial to contemporary electronics and the systems are tailored for manufacturers, service providers, and businesses seeking precise, efficient soldering of surface-mounted parts.

These systems operate on several fundamental principles: applying the correct solder paste to the PCB, positioning SMDs on the designated pads, and then heating the solder paste as the PCB progresses through the system to melt and solidify it, thereby forming a durable, conductive bond between the component and the PCB. This multi-stage process includes pre-heating to ready the PCB for components and reflow soldering to form solder joints under controlled temperatures in an inert environment.

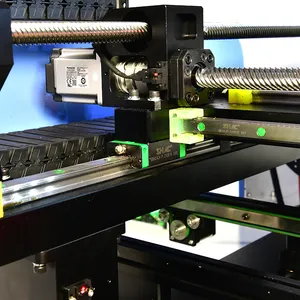

Automatic SMD Soldering Systems incorporate components like motors, controllers, and heating elements that work in unison for precise temperature and placement control. Some systems also feature vision systems for solder joint inspection. The adoption of robotics and artificial intelligence (AI) in these systems allows for complex, high-precision tasks, enhancing the productivity of electronic assembly lines.

Varieties of Automatic SMD Soldering Systems

Diverse automatic SMD soldering systems are available to suit various production requirements and preferences, each with distinct features for particular applications:

-

Reflow Ovens: Suited for small to medium batch production, these systems use a conveyor to transport PCBs through heated zones, culminating in a reflow zone where solder paste melts and a cooling zone for solidification.

-

Wave Soldering Machines: Best for high-volume production, these machines generate a solder wave that solders the board's exposed leads and pads, ideal for settings that demand uniform solder joints.

-

Selective Soldering Systems: Tailored for soldering specific board components, these systems are used for complex assemblies or with high-value parts sensitive to the soldering process.

-

Soldering Robots: These machines offer automated soldering for large-scale production, combining precise motion control with consistent heat delivery, commonly used in advanced industries like aerospace or electronics.

-

Hand Soldering Stations: While not fully automated, these stations employ a handheld soldering iron and separate solder feed, offering versatility for prototyping, repairs, and detailed soldering tasks.

Selecting an Automatic SMD Soldering System

Choosing an automatic SMD soldering system demands careful consideration of several factors to match your business's specific requirements.

First, assess the size and type of components you'll be soldering. For smaller or more delicate components, such as 0201 or 01005 resistors, a hot air system may be preferable for its precision and gentle heating. Conversely, a wave system might be more appropriate for larger components or traditional soldering methods.

Next, consider production volume. High-volume operations may benefit from conveyor systems for efficient board transport, while smaller-scale operations might opt for reflow systems or hand soldering tools for their lower production needs.

Finally, ensure the system integrates with your existing workflow and supports your preferred soldering method—reflow, wave, or hand soldering—to maintain operational consistency.

About Automatic SMD Soldering Systems on Alibaba.com

Alibaba.com is a premier global marketplace for sourcing Automatic SMD Soldering Systems, connecting businesses with a vast array of suppliers to fulfill diverse manufacturing needs. The platform offers a broad selection of automatic SMD soldering technologies from around the world, catering to both niche and large-scale enterprises.

The platform's dedication to streamlining global trade is reflected in its intuitive interface, multi-language support, and mobile accessibility, allowing buyers to efficiently explore options and benefit from services like order handling and delivery.

Alibaba.com also prioritizes secure transactions, offering services like Trade Assurance to protect payments until delivery is confirmed. Whether outfitting a startup or scaling up an established business, Alibaba.com provides a wide array of Automatic SMD Soldering Systems that promise quality and reliability.

Common FAQs for Automatic SMD Soldering Systems

What is the purpose of an automatic SMD soldering system?

Automatic SMD soldering systems are indispensable for the precise, efficient soldering of SMDs onto PCBs, crucial in high-speed, mass production settings.

How does an automatic SMD soldering system function?

These systems utilize a blend of robotic precision, advanced sensors, and thermal control to automatically solder SMDs onto PCBs, ensuring consistent quality and productivity.

What should be considered when selecting an automatic SMD soldering system?

Selecting an automatic SMD soldering system involves evaluating your manufacturing process needs, the types of SMDs used, automation levels, safety features, and available after-sales services.

Can automatic SMD soldering systems accommodate various SMD types?

Most advanced automatic SMD soldering systems are versatile enough to handle a range of SMD types, but it's crucial to confirm that the chosen system is compatible with the specific SMD packages in your production.

How can one ensure consistent quality with an automatic SMD soldering system?

To maintain consistent quality, opt for a system with precise temperature and timing control, and adhere to regular maintenance and the manufacturer's guidelines.

What after-sales services are typically offered with automatic SMD soldering systems?

After-sales services may include video technical support, online assistance, field maintenance, repair services, or access to engineers for overseas machinery servicing, varying by supplier.

How does the environmental impact of automatic SMD soldering systems compare to manual methods?

Designed for high-volume production, automatic SMD soldering systems are generally more eco-friendly than manual methods, yielding consistent results that reduce errors and waste.

Are portable automatic SMD soldering systems available?

Portable automatic SMD soldering systems are available for mobile applications or use in various locations, often featuring battery operation or lightweight designs for easy transport.

Is it possible to customize an automatic SMD soldering system on Alibaba.com?

Alibaba.com facilitates connections with suppliers who can offer customized automatic SMD soldering systems tailored to specific needs.