Introduction to Aluminum Centrifugal Casting

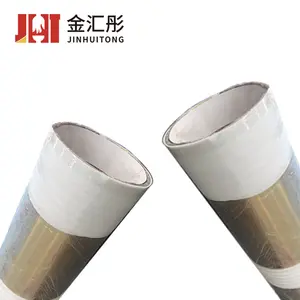

Aluminum centrifugal casting is a specialized process where molten aluminum is poured into a rapidly spinning mold, allowing the centrifugal force to form the metal into a desired shape. This technique is pivotal in creating components with fine grain structures and enhanced mechanical properties, making it a preferred method for various industries.

Types and Applications

The versatility of centrifugal casting aluminum is evident in its array of types, each suited for specific applications. From intricate parts for the automotive sector to robust components for industrial machinery, this process is adaptable to a multitude of designs and requirements. The adaptability of aluminum centrifugal casting ensures its applicability across sectors, including aerospace, transportation, and energy.

Features and Materials

Centrifugal casting aluminum stands out for its ability to produce parts with high integrity and excellent mechanical properties. The process utilizes various aluminum alloys, each selected for its unique characteristics, such as corrosion resistance, strength-to-weight ratio, and thermal conductivity. The selection of material is critical, influencing the casting's performance in its final application.

Advantages of the Process

The aluminum centrifugal casting process offers numerous advantages. It minimizes porosity, enhances metallurgical properties, and allows for the creation of parts with complex geometries without the need for welding or assembly. These benefits make centrifugal casting aluminum a cost-effective choice for producing high-quality components.

Specifications and Performance

When sourcing aluminum centrifugal casting machinery, it is essential to consider the specifications that align with your production needs. Equipment varies by size, power, and capacity, designed to meet the diverse demands of the casting industry. Performance factors such as efficiency, durability, and precision engineering are critical in selecting the appropriate machinery for your operations.

Choosing the Right Supplier

Navigating the vast selection of suppliers offering aluminum centrifugal casting and related machinery can be daunting. It is crucial to engage with suppliers who can provide detailed information about their machinery, ensuring that their offerings meet your specific requirements. Inquire about the engineering and performance of their equipment to make an informed decision for your casting needs.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4