Popular in your industry

Related Searches:

Top categories

About 2500 ton aluminum die casting machine

Introduction to Aluminum Die Casting Machines

Aluminum die casting is a precision manufacturing process where molten aluminum is injected into a mold, known as a die, under high pressure. A 2500 ton aluminum die casting machine stands at the forefront of this industry, offering substantial clamping force for the production of large and complex aluminum parts. This category of machinery is pivotal for industries requiring high-volume production of aluminum components with excellent accuracy and repeatability.

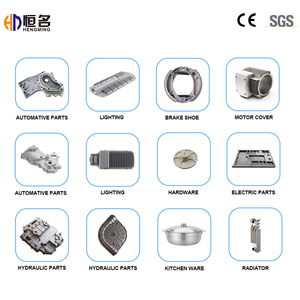

Types and Applications

Die casting machines come in various types, including cold chamber and hot chamber machines. The 2500 ton aluminum die casting machine typically falls under the cold chamber category, ideal for metals with high melting points like aluminum. These machines serve critical roles in automotive, aerospace, electronics, and industrial machinery sectors, where the integrity and strength of components are paramount.

Features and Materials

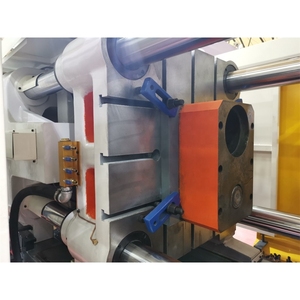

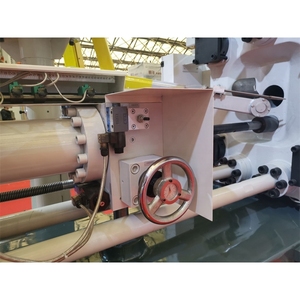

The construction of a 2500 ton die casting machine involves robust materials capable of withstanding the stresses of die casting. Features often include advanced hydraulic systems for precision control, efficient cooling systems to maintain optimal temperatures, and state-of-the-art injection systems for consistent quality. The emphasis is on durability and performance stability throughout the machine's lifespan.

Advantages of Using a 2500 Ton Machine

Utilizing a heavy-duty die casting machine such as the 2500 ton model offers numerous advantages. Its ability to produce large parts with intricate designs in a single cycle enhances productivity. The machine's precision reduces waste and the need for secondary machining, while its operational reliability minimizes downtime. Additionally, safety features are integrated to safeguard operators during the die casting process.

Operational Efficiency and Reliability

The operational efficiency of a large capacity die casting machine is a key consideration for businesses aiming to optimize their production lines. These machines are engineered to maintain consistent performance, with low failure rates and availability of spare parts to ensure continuous operation. The reliability of these machines translates into sustained production capabilities for businesses.

Choosing the Right Machine

Selecting the appropriate aluminum die casting equipment is crucial for manufacturers. Factors such as part size, material properties, and production volume must be considered to find a machine that meets specific manufacturing needs. While Alibaba.com does not endorse any particular brand or make guarantees, the platform offers a diverse array of options to cater to the varied requirements of the die casting industry.