Understanding Oil Heat Exchangers

An oil heat exchanger is a critical component in managing the temperature of oil in various industrial processes. This device facilitates the transfer of heat between oil and other fluids, ensuring optimal operating temperatures are maintained. The efficiency of an oil heat exchanger is paramount in industries such as oil and gas, power generation, and manufacturing, where precise temperature control is essential.

Types and Applications

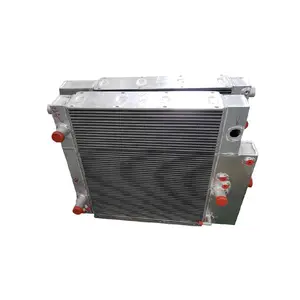

The versatility of oil heat exchangers is evident in their various types and applications. In the oil and gas industry, these exchangers play a vital role in maintaining the fluidity of crude oil during processing. Types of heat exchanger in oil and gas industry include shell and tube, plate, and air-cooled designs, each serving specific functions from refining to transportation. The lube oil cooler heat exchanger is another example, commonly used to prevent overheating in machinery by cooling lubricating oil.

Materials and Features

Materials used in oil heat exchangers, such as copper, stainless steel, and titanium, are selected for their thermal conductivity and durability. Copper exchangers, for instance, are often utilized in scenarios where corrosion resistance and antimicrobial properties are beneficial, such as in oil to water heat exchangers. Stainless steel variants are known for their rapid heat transfer capabilities, making them suitable for large-scale water treatment operations. Titanium oil heat exchangers offer high-temperature resistance, ideal for harsh environments like power plants.

Advantages of Oil Heat Exchangers

The advantages of using an oil heat exchanger are numerous. They contribute to energy efficiency by recovering waste heat and reducing the thermal load on systems. In the realm of environmental impact, heat exchangers such as the hydraulic oil heat exchanger can help in reducing the carbon footprint of hydraulic systems by maintaining oil viscosity at optimal levels for energy-efficient operation.

Selecting the Right Oil Heat Exchanger

Choosing the right oil heat exchanger requires a thorough understanding of the specific industry needs. For instance, a fuel oil heat exchanger is designed to support the transfer of heat in fuel oil applications, while a refinery exchanger is tailored for the robust demands of oil refining processes. It is crucial to consider factors such as fluid properties, operating temperatures, and environmental conditions when selecting an exchanger.

Conclusion

Alibaba.com's extensive catalog offers a diverse range of oil heat exchangers to meet the needs of various industrial applications. From the oil furnace heat exchanger for heating solutions to specialized heat exchanger oil and gas equipment for energy sectors, the platform connects buyers with a multitude of suppliers to find the appropriate heat exchange solutions.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4