Introduction to PP Spunbond Nonwoven Machinery

Polypropylene (PP) spunbond nonwoven machines represent a specialized category of textile machinery designed for the production of nonwoven fabrics. These machines utilize a spunbond process, which involves the conversion of thermoplastic polymer granules into continuous filaments, subsequently laid down into a web and bonded to create nonwoven fabrics. This technology is pivotal in fabricating materials for a myriad of applications, from medical to geotextiles.

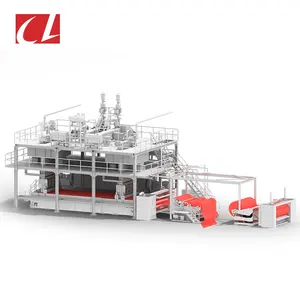

Types and Configurations

The diversity of PP spunbond nonwoven machines caters to various production needs. Single-beam, double-beam, and multi-beam machines are common configurations, each offering different widths and throughput capabilities. The choice of machine depends on the intended fabric properties and production volume, with each type ensuring the production of consistent and uniform nonwoven fabrics.

Applications and Features

PP spunbond nonwoven fabrics are integral in numerous sectors due to their versatility. These machines produce fabrics for medical disposables, agricultural covers, and shopping bags, among others. Key features of these machines include precision control systems, which allow for adjustments in fabric weight and strength, and automation that enhances production efficiency. The nonwoven equipment is engineered to deliver continuous operation with minimal downtime, contributing to steady production cycles.

Material and Advantages

The primary material used in PP spunbond nonwoven machines is polypropylene due to its excellent chemical resistance and mechanical properties. The resultant nonwoven fabrics are known for their durability, recyclability, and hygiene, making them suitable for environmentally conscious production. The machinery's advanced technology ensures energy-efficient operation, reducing the overall environmental impact.

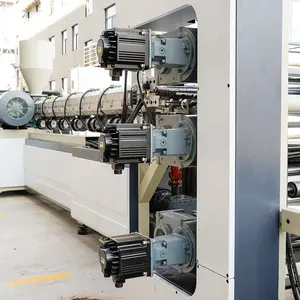

Operational Efficiency and Safety

Operational efficiency is a hallmark of modern PP spunbond nonwoven machinery. With automated process controls, these machines maintain high production speeds while ensuring uniformity in the nonwoven fabric. Safety features are embedded within the machinery design, safeguarding operators from potential hazards and contributing to a secure working environment.

Choosing the Right Machine

Selecting the appropriate PP spunbond nonwoven machine is crucial for meeting specific production goals. Factors such as machine width, speed, and filament fineness play a significant role in the decision-making process. Prospective buyers can explore a comprehensive range of machines on Alibaba.com, each designed to meet the diverse needs of the nonwoven fabric industry.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4