Introduction to Plywood Boring Machines

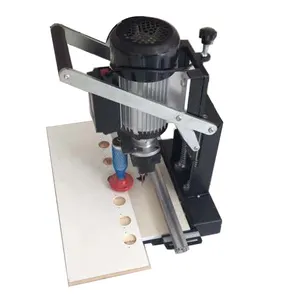

Plywood boring machines are specialized tools designed for creating precise holes in wood materials. These machines are essential in woodworking where accuracy and efficiency are paramount. They are engineered to handle various drilling requirements, from simple cylindrical holes to complex tapered or shaped apertures.

Types and Applications

The versatility of plywood boring machines is evident in their types and applications. Horizontal boring machines utilize a spindle aligned with the table, ideal for straightforward drilling tasks. In contrast, vertical boring machines demand the workpiece to be clamped before the operation, suitable for handling more intricate boring work. Line boring machines, supporting a bar at both ends, excel in drilling holes in large or long pieces of wood. These machines cater to a range of applications, from furniture making to construction, where precision drilling is required.

Features and Materials

Plywood boring machines are constructed with durability in mind, using robust materials that withstand the rigors of heavy use. They come equipped with features that enhance user control and precision, such as adjustable speed settings and depth stops. The construction of these machines often involves metals and composites that ensure longevity and consistent performance.

Advantages of Modern Boring Machines

The efficiency of plywood boring machines is a significant advantage, allowing for rapid completion of tasks that would take much longer manually. These machines are designed to operate with minimal noise and without emitting unpleasant odors, making them suitable for various work environments. Their ability to drill holes of varying shapes and depths with precision makes them an indispensable tool in the woodworking industry.

Choosing the Right Plywood Boring Machine

Selecting the appropriate plywood boring machine depends on the specific needs of the task at hand. Factors to consider include the type of holes required, the volume of work, and the nature of the wood being drilled. Machines are available to suit different scales of operation, from small workshops to large-scale manufacturing.

Efficiency and Practicality

In conclusion, plywood boring machines are a testament to the advancements in woodworking technology, offering practical solutions that enhance productivity. These machines are a valuable addition to any woodworking operation, providing the capability to execute precise drilling tasks with ease and efficiency.

浙公网安备 33010002000092号

浙公网安备 33010002000092号 浙B2-20120091-4

浙B2-20120091-4